MDF vs. plywood: Which material should you choose?

When I walked through the large furniture showrooms at NeoCon this past summer, I noticed the prominence of plywood being used. I could easily tell the material by the exposed edges, revealing layers of veneer. I sometimes saw that an edgebanding was applied on MDF tabletops to make the edge look like exposed plywood.

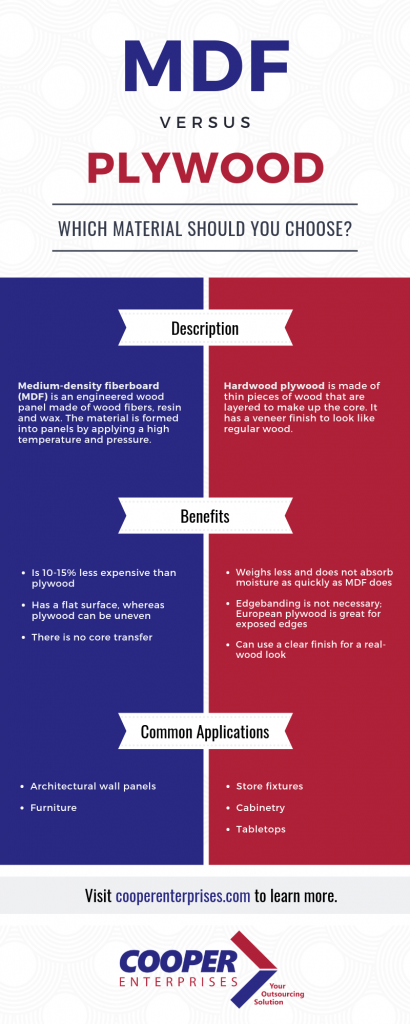

When you’re able to make MDF look like plywood, I thought it would be interesting to investigate the differences between those two materials. I spoke with Jerry Truex, our account executive for the Midwestern states, who has extensive knowledge of the different types of board. Our conversation resulted in the infographic below:

View a PDF version of the MDF vs. Plywood infographic

The Materials

Medium-density fiberboard (MDF) is composed of wood fibers, wax and resin, which are then formed into a panel by applying a high temperature and pressure. The standard thicknesses of MDF range between ¼ and 1¼ inches thick. MDF has no grain pattern and is free of knots, as it is a flat, smooth panel. MDF is commonly used for furniture and architectural millwork. High-end environments like court rooms, for example, use MDF for its consistency and smooth appearance.

The core of plywood is made of stacked wood veneers that are bonded with adhesive. The direction of the grain alternates 90 degrees between each sheet of veneer. A face veneer, such as maple or walnut, is applied to the top of the core. Common uses of plywood include store fixtures, cabinetry and tabletops.

Benefits and Drawbacks

MDF is a common alternative to plywood because MDF is generally 10-15 percent less expensive than plywood. MDF also has a uniform, smooth surface. Plywood can often be uneven due to knots and inconsistent veneer thicknesses.

If a dark stain is applied to plywood, you may experience “core transfer.” This is when you can start to see some of the core grains, which run in opposite directions. Since MDF does not have a grain, you will not experience this with MDF.

However, plywood weighs less and does not absorb moisture as quickly. Plywood does not have to be edgebanded. European plywood is great for exposed edges. Domestic plywood should be avoided if exposed edges are desired; the veneers are thicker, and voids are much more noticeable.

Nevertheless, if you want a less expensive panel but with exposed, plywood edges, you could opt for using MDF and applying a plywood-looking edgebanding. This edgebanding can only be applied to a straight edge and cannot be applied to a radius edge.

At Cooper Enterprises, we have experience using both of these materials. What are your thoughts on using MDF and plywood? We’d love to hear from you with comments or questions.

Blog by Rachel Brumenschenkel, Marketing Specialist